All our PhD and postdoctoral fellowships are available on VITO website: https://vito.be/en/jobs

Master/Bachelor Internships

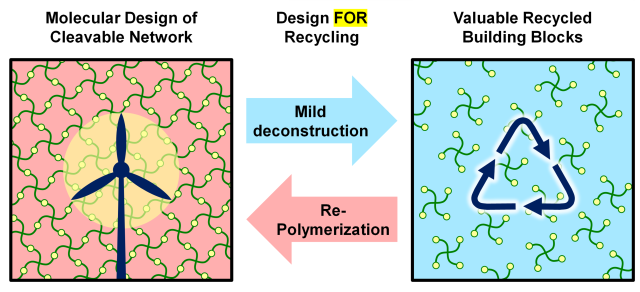

Cleavable Thermosets Designed For Chemical Recycling

The growing use of polymeric materials demands new end-of-life strategies, especially for thermosets such as polyurethane foams, epoxy resins and crosslinked acrylic coatings. These materials offer outstanding performance but are extremely difficult to recycle because of their permanent covalent networks. Today, most thermosets still end up in landfills or undergo destructive treatment.

This internship focuses on the design and synthesis of thermosetting polymers that can be selectively broken down under mild chemical conditions. By integrating cleavable bonds into the network structure, these materials can be depolymerized into valuable fragments, enabling more circular use and improved sustainability.

The student will work on cleavable epoxy or polyurethane systems, evaluate their structure, and study their controlled deconstruction through mild solvolysis or hydrolysis routes.

Daily tasks and skills to be developed

- Synthesis of cleavable monomers and thermoset formulations

- Structural analysis via NMR and FT-IR

- Thermal characterization (DSC, TGA)

- Network evaluation (gel content, swelling, crosslink density)

- Chemical recycling tests under mild conditions and analysis of recovered fragments

The student will perform hands-on laboratory work, keep accurate records, and report results regularly. The project’s complexity will be adapted to the candidate’s progress.

Requirements:

You are enrolled in a Bachelor’s or Master’s program in Chemistry, Chemical Engineering, Materials Science or related fields. You are motivated, proactive and comfortable with laboratory work. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Richard Vendamme richard.vendamme [at] vito.be (richard[dot]vendamme[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

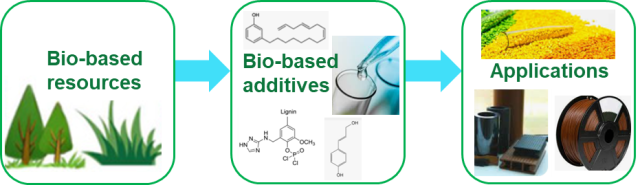

DEVELOPMENT OF SAFE AND SUSTAINABLE POLYMER ADDITIVES DERIVED FROM RENEWABLE RESOURCES

Commercial polymers invariably contain additives. Functional additives such as flame retardants, UV stabilizers, antioxidants, and plasticizers, are widely used in both thermoplastics and thermosets to enhance processability, durability, and end-use performance. At VITO, we aim to partially replace petroleum-based additives with renewable alternatives, with a particular focus on lignin. As the second most abundant natural polymer on Earth (after cellulose) and the only large-scale natural source of aromatic structures, lignin offers significant potential. However, despite its abundance, lignin remains underexploited and is still predominantly burned as a low-value fuel.

This project aims to synthesize new, safe, and sustainable polymer additives derived from renewable resources. Depending on the chosen biobased precursor, various chemical modification strategies will be designed and developed. The resulting bio-additives will then be incorporated into (bio)polymers through thermal extrusion to assess their performance.

The work will involve a range of analytical and characterization techniques, including FTIR, GPC, NMR, DSC, and TGA, as well as mechanical testing methods such as rheology, DMA, and tensile testing.

Requirements:

Hold a bachelor (or third or last year bachelor) in Chemistry/Polymer Chemistry/Chemical Engineering/Organic Chemistry. You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Ir. Maarten Rubens: maarten.rubens [at] vito.be (maarten[dot]rubens[at]vito[dot]be) & Dr. Sandra Corderí Gándara, sandra.corderigandara [at] vito.be (sandra[dot]corderigandara[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

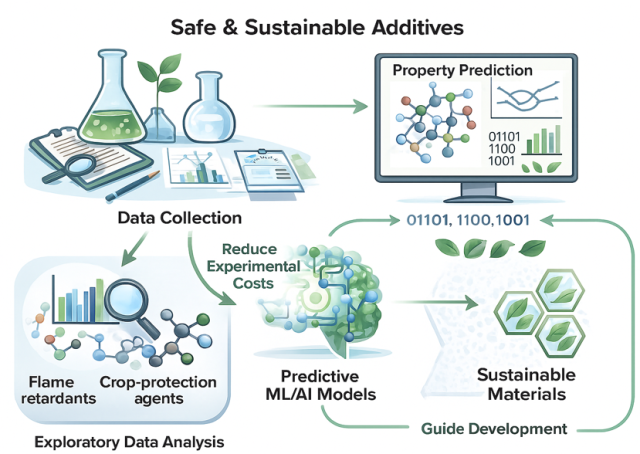

In silico property prediction for safe and sustainable polymer additives

The demand for safe and sustainable additives is increasing rapidly. Traditionally, additives were selected primarily for their functional performance, with limited consideration for their potential impact on human health or the environment. Today, computational (in silico) property prediction plays a crucial role in the development of high-tech, sustainable, safe, green, and biobased additives. These approaches help accelerate research, reduce experimental costs, and provide deeper insights into structure–property relationships.

This internship focuses on developing machine learning (ML) and artificial intelligence (AI) models for a range of additive families, such as flame retardants and crop-protection agents. Data will be collected from scientific literature and/or internal datasets. Through exploratory data analysis, the student will identify key molecular features and performance-determining properties. Based on these insights, predictive ML/AI models will be designed to estimate additive performance and guide the development of next-generation sustainable materials.

Learning outcomes:

The student will gain hands-on experience with:

- A variety of ML/AI techniques for chemical and materials applications

- Data analysis, feature engineering, and model validation methods

- A complete chemical informatics workflow: from raw data to property prediction

- Mining and curating scientific data from literature and databases

Requirements:

You are enrolled in a Bachelor’s or Master’s program in Chemistry, Chemical Engineering, Material Science, Data science (with interest in chemistry), or a related field. You are motivated, proactive and interested in safe and sustainable technologies. You have a programming experience in Python. Experience with git, MLFlow, iceberg tables, scikit-learn, PyTorch, Tensorflow and HPC environments are a plus. You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Ir. Maarten Rubens: maarten.rubens [at] vito.be (maarten[dot]rubens[at]vito[dot]be) & Michiel Jacobs, michiel.jacobs [at] vito.be (michiel[dot]jacobs[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

Economic feasibility and environmental impact of sustainable processes

Are you interested in new, sustainable processes and are you particularly curious about their economic feasibility and environmental impact? Then techno-economic analysis are for you. With new technologies there are often still many uncertainties and it is unclear which options are most promising. Is the investment cost the deciding factor, or should we mainly reduce energy consumption or increase productivity? Which research goals need to be achieved? Our team tries to formulate answers to these questions in close cooperation with technology developers and searches for promising value chains with the help of techno-economic analyses. In a techno-economic analysis, we simultaneously examine the processes from a technical and economic point of view. We do these analyses on the basis of desktop research and through intensive communication with process developers.

The aim of this project is that you perform a techno-economic analysis for a topic that is of interest to the SPOT team (e.g. plastic recycling, biomass valorization and polymer formulation).

Requirements:

You hold a BS degree, are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are interested in emerging technologies and evaluating the sustainability of them.

Contact person:

Dr. Miet Van Dael: miet.vandael [at] vito.be (miet[dot]vandael[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

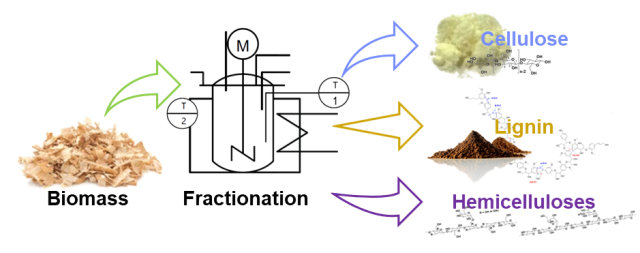

FRACTIONATION OF LIGNOCELLULOSES FOR ENHANCED VALORIZATION

Maturing and developing novel concepts for the fractionation of lignocellulosic biomass into its principal components cellulose, lignin, and hemicellulose is essential to provide renewable resources to the chemical industry. This is a crucial prerequisite to replace fossil-derived chemicals in a circular bioeconomy. However, the variability in terms of composition of lignocellulosic resources such as waste wood and agricultural residues limits the suitability for chemical conversion processes. The target of this work is to isolate purified lignin and cellulose fractions from industrial side or waste streams to enhance their valorization.

The focus of this internship opportunity will be on optimizing mild isolation procedures to obtain lignin fractions that can be readily used for the development of biomaterials or to facilitate bio-aromatics as platform chemicals. Lignin is an attractive but underutilized component of lignocellulosic biomass because of its aromaticity and hydroxyl functionalities that provide unique features such as antioxidant and antistatic properties, UV-absorption, and high thermal stability.

If you are interested in doing an internship in this field, you will gain hands-on experience on topics related to the lignin-first biorefinery concept. These topics are biomass characterization, biomass pre-treatments, fractionation/pulping chemistry, and targeted extraction of components from complex solutions containing dissolved lignocellulose components. Typical parameters to optimize in all cases are, for example solvent, temperature, catalyst, time and pressure.

What to expect / typical tasks:

- Perform biomass pre-treatments

- Perform (mechano-) chemical biomass fractionation in the laboratory

- Isolate principal biomass components

- Preparing samples for state-of-the-art analytical techniques such as

- Infrared spectroscopy (FTIR)

- Gel permeation chromatography (GPC)

- Nuclear magnetic resonance spectroscopy (NMR)

- Anion exchange chromatography (AEC)

- Processing data and learning how to interpret analytical results

Requirements:

You are a student of chemistry, chemical engineering or a related subject either at bachelor's or master's level. You are proactive, motivated and a team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Previous experience of working in a chemistry laboratory is a plus (e.g., practical courses at university, bachelor project, previous internship etc.).

Contact person:

Dr. Paul Jusner: paul.jusner [at] vito.be (paul[dot]jusner[at]vito[dot]be) & Dr. Balaji Sridharan: balaji.sridharan [at] vito.be (balaji[dot]sridharan[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

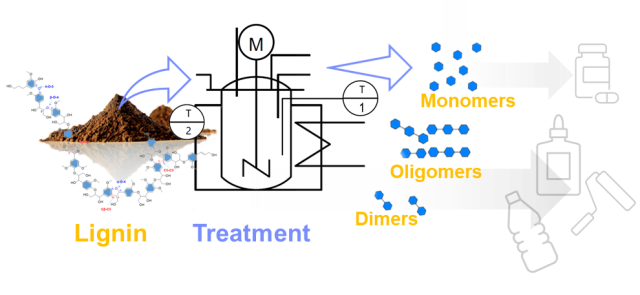

UPGRADING OF LIGNIN FOR BIOMATERIALS

Lignin is the most abundant renewable aromatic resource on earth and is one of the three main components of cell walls of higher plants such as trees and fibre plants. Large amounts of lignin are generated every day as a by-product in the pulp and paper industry and in bioethanol production facilities. Because of its complex and heterogenous molecular structure, it is not directly used for material applications and frequently burnt instead to generate process heat.

To take advantage of this biopolymer in a more efficient way, we are exploring alternative processes that permit the conversion of this valuable resource into an intermediate that is easier to handle and use. The target is to obtain more uniform and more reactive molecules that can be readily used for the development of biomaterials and turned into valuable platform chemicals. Such a technology is central to replace fossil resources used to produce, for example lignin-based PUs, epoxy resins, or acrylates.

The desired outcomes are lignin-derived aromatic compounds that are characterized by a lower molecular mass, a lower polydispersity, and high contents of functional groups that can be used for follow-up chemistry. If you would support this work in the framework of an internship, you will get hands-on experience in a fast-developing and dynamic research field.

What to expect / typical tasks:

- Perform experiments with high pressure reactors

- Preparation of catalyst beds

- Collecting and processing samples

- Preparing samples for state-of-the-art analytical techniques

- Gel permeation chromatography (GPC)

- Nuclear magnetic resonance spectroscopy (NMR)

- Gas chromatography (GC)

- Processing data and learning how to interpret analytical results

Requirements:

You are a student of chemistry, chemical engineering or a related subject either at bachelor's or master's level. You are proactive, motivated and a team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Paul Jusner: paul.jusner [at] vito.be (paul[dot]jusner[at]vito[dot]be) & Dr. Ir. Elias Feghali: elias.feghali [at] vito.be (elias[dot]feghali[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

CHEMICAL RECYCLING OF ENERGY AND CONSTRUCTION THERMOSETS

The increasing use of thermoset polymers in energy and construction applications, such as epoxy composites, polyurethane foams, and cross-linked resins, has led to a rapidly growing waste stream for which no sustainable recycling routes currently exist. For example, due to their permanently cross-linked network, thermosets cannot be remelted or mechanically reprocessed, resulting in landfilling or downcycling as the dominant end-of-life options. Developing efficient chemical recycling technologies is therefore crucial to recover valuable building blocks and reduce environmental impact in these high-performance sectors.

In this context, this project aims to develop innovative catalytic depolymerization strategies for the chemical recycling of energy and construction thermosets. Target materials include epoxy resins, polyurethanes, and other cross-linked systems commonly used in wind turbine blades, insulation foams, and structural composites. The project will explore pathways capable of selectively breaking thermoset networks and recovering monomers or oligomers of high quality. In contrast to existing approaches that focus mainly on thermoplastics or require pure, well-defined streams, this project also emphasizes the treatment of realistic and heterogeneous thermoset waste.

Recovered materials and reaction progress will be characterized using techniques such as FTIR, GPC, GC, NMR, DSC, and TGA to gain insight into depolymerization mechanisms and assess the potential for a closed-loop recycling strategy.

Requirements:

You hold a BS (or last year BS) in Chemistry/Polymer Chemistry/Chemical Engineering. You have basic laboratory skills including lab safety, basic reporting skills (word, PowerPoint). You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Ir. Elias Feghali: elias.feghali [at] vito.be (elias[dot]feghali[at]vito[dot]be) & Dr. Ir. Carlos Marquez Admade: %20carlos.marquezadmade [at] vito.be (carlos[dot]marquezadmade[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

BIOBASED LIGNIN-EPOXY-BASED MATERIALS FABRICATION, OPTIMIZATION AND FINAL PROPERTIES ANALYSIS

Utilizing biobased materials in the circular economy fosters sustainability by reducing reliance on finite resources and minimizing environmental impact. Embracing biobased materials not only mitigates waste generation but also promotes a shift towards a more ecologically balanced and resource-efficient society. The Sustainable Polymer Technologies (SPOT) team at VITO is dedicated to investigating new strategies for creating biobased polymers and composites. Knowledge in formulation, polymerization conditions, material production and characterization, provide us with a deep understanding of how to design biobased materials suitable for a large number of applications such as, coatings, adhesives, insulators, foams. In order to achieve biobased materials, we relie in molecules or oligomers derived from biomass, mainly lignin called “LignoStarters”, which have been functionalized with reactive functional groups like hydroxyl, acrylate or epoxide, among others. This student project centers on optimizing the fabrication of epoxy biobased materials by focusing in the initial components dispersion, modifying formulation parameters and modulating polymerization conditions. This will allow the participant to produce a collection of materials with diverse structure, thermal and mechanical properties that will be analysed and interpretated (NMR, FTIR, GPC, DSC, DMA and TGA). By the end of the project, it is expected that the student will be able to extract precise structure-properties relationship from the biobased material fabricated.

Requirements:

Hold a bachelor (or third or last year bachelor) in Chemistry/Polymer Chemistry/Chemical Engineering/Organic Chemistry. You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Marc Comi Bonachi (marc.comibonachi [at] vito.be (marc[dot]comibonachi[at]vito[dot]be)) & Dr. Sandra Corderí Gándara (sandra.corderigandara [at] vito.be (sandra[dot]corderigandara[at]vito[dot]be))

Please include your CV, study program, preferred internship period, and a short motivation.

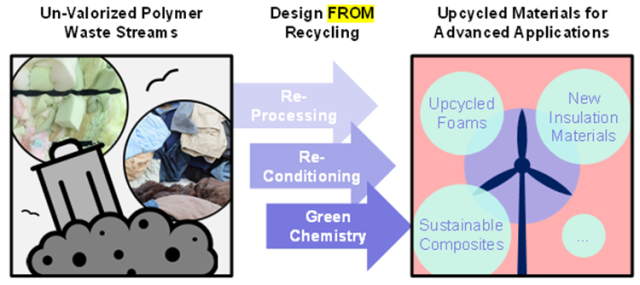

Design-from-Recycling: Turning Waste into New Materials

Polymer and fibre-based waste streams are produced in vast quantities, yet only a small fraction is currently recycled into high-value materials. Conventional mechanical recycling often requires pure waste inputs and results in downcycled products. At VITO, we are exploring a complementary approach: Design-from-Recycling, where new materials are created directly from existing waste, rather than starting from virgin monomers.

The internship will contribute to this broad research direction. Possible topics include:

- Transforming fibre-rich waste (textiles, paper, cardboard) into consolidated materials or panels using simple physical or chemical pre-treatments

- Reorganizing polymeric or composite waste into new structures through pressing, impregnation, blending or architectural modification

- Using recycled building blocks (e.g. monomers, polyols, oligomers obtained from chemical recycling) as feedstocks for new polymers or resins

Depending on your interests and the project timing, you may process waste materials, optimize experimental conditions, prepare prototype samples, and characterize their structure and properties.

Techniques and learning opportunities

- FTIR, DSC, TGA, density and moisture analysis

- Mechanical testing (bending, tensile, compression, extrusion), microscopy

- Basic rheology or DMA

- Sample preparation (shredding, mixing, impregnation, pressing)

The student will perform hands-on laboratory work, keep accurate records, and report results regularly. The project’s complexity will be adapted to the candidate’s progress.

Requirements:

You are enrolled in a Bachelor’s or Master’s in Chemistry, Chemical Engineering, Materials Science, Polymer Science or related fields. You are proactive, motivated by sustainability and circular materials and an excellent team player who enjoys working in a multidisciplinary environment. You are interested to acquire hands-on experience by running innovative experimental set-ups. You have a result-driven character capable of translating theory to practice and vice versa and are able to find solutions. You are fluent in English and eager to write scientific papers and/or patents.

Contact person:

Dr. Richard Vendamme: richard.vendamme [at] vito.be (richard[dot]vendamme[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation

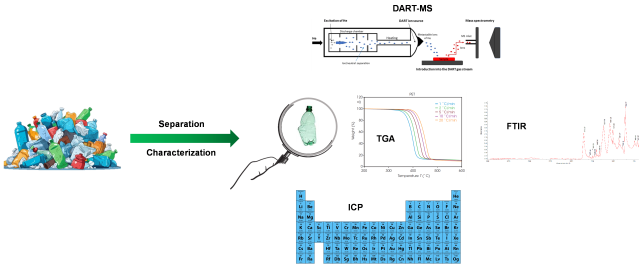

ANALYSES OF WASTE STREAMS AND ASSESSMENT OF THEIR POTENTIAL FOR CHEMICAL RECYCLING

The global production of diverse plastics continues to rise, resulting in increasingly heterogeneous waste streams that pose major challenges for circular plastics technologies. Unlike single-polymer waste, real waste streams typically contain complex mixtures of polymers and additives. These impurities strongly hinder both mechanical and chemical recycling by causing catalyst deactivation, undesired side reactions, poor product purity, or even operational issues such as corrosion and fouling. Despite their importance, a detailed and comprehensive study on the full polymer composition and elemental impurity profiles of plastic waste streams remain very limited.

This project aims to generate a systematic and in-depth analysis of commonly generated plastic waste streams (e.g. collected from rivers or sorting facilities) and to assess their suitability and constraints for chemical recycling routes. The project will investigate a diverse set of representative products aiming at a deep understanding of the heterogeneity present in actual recycling input streams. To this end, a combination of advanced analytical techniques will be employed, including FTIR spectroscopy, TGA, ICP and DART-MS to determine both the polymer composition and the elemental impurities present in the stream. The collected data will be used to identify critical contamination patterns, evaluate the compatibility of various waste streams with catalytic depolymerization or solvent-based purification strategies, and map out the pretreatment steps required to achieve high-quality recycled outputs.

By analysing real-world waste composition and assessing its potential for recycling process, this project will provide essential insights for designing more efficient, cost-effective, and circular chemical recycling technologies for the plastic sector.

Requirements:

You hold a BS (or last year BS) in Chemistry/Polymer Chemistry/Chemical Engineering. You have basic laboratory skills including lab safety, basic reporting skills (word, PowerPoint). You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are fluent in English eager to write reports, scientific papers and/or patents.

Contact person:

Dr. Kathy Elst: %20kathy.elst [at] vito.be (kathy[dot]elst[at]vito[dot]be) & Dr. Ir. Carlos Marquez Admade: %20carlos.marquezadmade [at] vito.be (carlos[dot]marquezadmade[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.

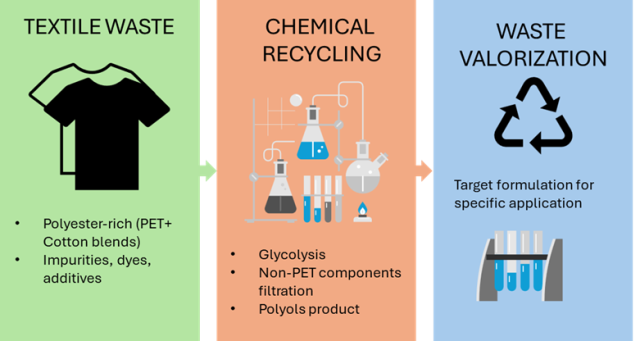

PRODUCTION OF POLYOLS FROM PET TEXTILE WASTE

The rapid expansion of textile production and consumption generates growing amounts of polyester-rich waste, primarily composed of polyethylene terephthalate (PET) in pure or blended forms. Converting these residues into value-added products through chemical recycling represents a key step toward circular material flows. Among the most promising products are polyester-based polyols, which can serve as versatile intermediates for various applications.

This internship will focus on optimizing the glycolysis-based production of polyols from PET-containing textile waste. The main objective is to establish robust and reproducible process conditions capable of delivering polyols with well-controlled molecular weight, viscosity, and chemical functionality. Emphasis will be placed on process parameters such as glycol type and ratio, catalyst selection, reaction temperature, and residence time, with the goal of maximizing yield and product consistency.

Key tasks will include:

- Characterizing the input textile materials (composition, intrinsic viscosity, and additives).

- Systematically assessing reaction parameters to identify optimal depolymerization conditions.

- Comparing polyols obtained from textile-derived PET to those from reference PET materials.

- Conducting analytical characterization (FTIR, TGA, GPC, elemental analysis) to correlate structure and properties with reaction conditions.

While particular attention will be given to process optimization, secondary studies may evaluate how impurities or non-PET components present in real waste streams influence reaction performance and product quality.

The overarching goal is to develop a flexible, scalable protocol for producing high-quality polyester-based polyols from textile waste, contributing to a sustainable pathway for polymer circularity in the textile value chain.

Requirements:

You hold a BS (or last year BS) in Chemistry/Polymer Chemistry/Chemical Engineering. You have basic laboratory skills including lab safety, basic reporting skills (word, PowerPoint). You are proactive, motivated and an excellent team player who enjoys working in a multidisciplinary environment. You are fluent in English eager to write reports, scientific papers and/or patents.

Contact person:

Dr. Kathy Elst: %20kathy.elst [at] vito.be (kathy[dot]elst[at]vito[dot]be) & Dr. Chiara Fiorillo: chiara.fiorillo [at] vito.be (chiara[dot]fiorillo[at]vito[dot]be)

Please include your CV, study program, preferred internship period, and a short motivation.